I-API600 Class 900 OS&Y Cast Steel Gate Valve

I-GAV701-900

Incazelo Yomkhiqizo

I-API600 Class 900 OS&Y Cast Steel Gate Valve isetshenziswa kakhulu ezimbonini ezidinga amandla aphezulu kanye nezinga lokushisa eliphezulu. Lawa ma-valve avame ukusetshenziswa ekukhiqizeni uwoyela negesi, ukucwengisiswa, i-petrochemical, ukukhiqizwa kwamandla, kanye nezinqubo zezimboni lapho isidingo sezixazululo ezithembekile neziqinile zokubeka uphawu kubaluleke kakhulu.

Isilinganiso se-Class 900 sibonisa ukuthi i-valve yakhelwe ukumelana nezingcindezi ezifika kumaphawundi angu-900 iyintshi yesikwele (psi), okuyenza ifaneleke kahle ezindaweni ezidinga kakhulu lapho kunezimo zokucindezela okukhulu. Ukwengeza, umklamo we-OS&Y (Outside Screw and Yoke) unikeza ukunakekelwa kalula kanye nenkomba ebonakalayo yendawo yevalvu, ithuthukise ngokwengeziwe ukufaneleka kwayo kwezinhlelo zokusebenza ezibucayi.

Sekukonke, iValve Yesango Lensimbi Ye-Class 900 idingeka kakhulu ezimbonini ezidinga ukusebenza okuthembekile ngaphansi kwengcindezi eyinselele nezimo zokushisa.

Izici

Uhlolojikelele Lomkhiqizo

Ububanzi bungakhiwa ukuze buhambisane nohlelo lwakho lokusebenza, ngokwakhiwa komzimba, izinto ezibonakalayo, nezici ezihambisanayo ezithuthukisiwe ukuze zihlangabezane nezidingo zenqubo yakho. Njengoba isitifiketi se-ISO 9015, sisebenzisa izindlela ezihlelekile zokuqinisekisa ikhwalithi ephezulu, ungaqinisekiswa ngokwethembeka okuvelele nokusebenza kokuvala ngokuphila kokuklama kwempahla yakho.

Imfuneko Yezobuchwepheshe

· Idizayini Nokukhiqiza Ivumelana Ne-API 600

· Ubukhulu be-Flange Buvumelana ne-ASME B16.5

· Ubukhulu bobuso nobuso Buvumelana ne-ASME B16.10

· Testing Conform to API 598

· Imodi yokushayela: isondo lesandla, igiya le-bevel, ugesi

Ukucaciswa

| Igama Lengxenye | Okubalulekile |

| Umzimba | I-A216-WCB |

| I-Wedge | I-A216-WCB+CR13 |

| I-Bonnet Stud Nut | I-A194-2H |

| I-Bonnet Stud | I-A193-B7 |

| Isiqu | I-A182-F6a |

| Ibhonethi | I-A216-WCB |

| I-Stem Back Seat | I-A276-420 |

| Iphinikhodi ye-eyebolt | Insimbi Yekhabhoni |

| Isondo lesandla | I-Ductile Iron |

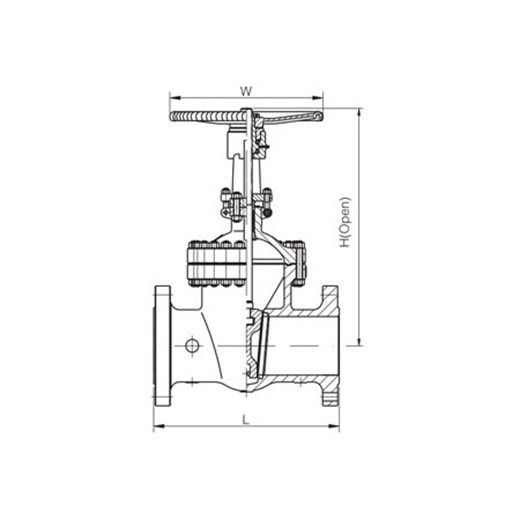

I-wireframe yomkhiqizo

Idatha yobukhulu

| Usayizi | in | 2 | 21/2 | 3 | 4 | 6 | 8 | 10 | 12 | 14 | 16 | 18 | 20 | 24 |

| mm | 50 | 65 | 80 | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 | |

| L/L1 (RF/BW) | in | 14.5 | 16.5 | 15 | 18 | 24 | 29 | 33 | 38 | 40.5 | 44.5 | 48 | 52 | 61 |

| mm | 368 | 419 | 381 | 457 | 610 | 737 | 838 | 965 | 1029 | 1130 | 1219 | 1321 | 1549 | |

| L2 (RTJ) | in | 14.62 | 16.62 | 15.12 | 18.12 | 24.12 | 29.12 | 33.12 | 38.12 | 40.88 | 44.88 | 48.5 | 52.5 | 61.75 |

| mm | 371 | 422 | 384 | 460 | 613 | 740 | 841 | 968 | 1038 | 1140 | 1232 | 1334 | 1568 | |

| H (VULA) | in | 19.62 | 21.5 | 22.5 | 26.62 | 35.5 | 43.5 | 53 | 60 | 74.88 | 81 | 87 | 101 | 104 |

| mm | 498 | 547 | 573 | 678 | 900 | 1103 | 1345 | 1525 | 1900 | 2055 | 2215 | 2565 | 2640 | |

| W | in | 10 | 10 | 12 | 18 | 20 | 24 | 26 | 29 | 32 | 32 | 36 | 38 | 40 |

| mm | 250 | 250 | 300 | 450 | 500 | 600 | 640 | 720 | 800 | 800 | 950 | 950 | 1000 | |

| WT (Kg) | I-RF/RTJ | 74 | 101 | 131 | 172 | 335 | 640 | 1100 | 1600 | 2250 | 2850 | 3060 | 3835 | 4900 |

| BW | 54 | 78 | 105 | 135 | 260 | 515 | 920 | 1380 | 2010 | 2565 | 2485 | 3250 | 4065 |