I-API600 Class 150 OS&Y Cast Steel Gate Valve

I-GAV701-150

Incazelo Yomkhiqizo

I-API600 Class 150 OS&Y Cast Steel Gate Valve ihlanganisa izinto zekhwalithi ephezulu nezici zedizayini ukuze kube lula ukulawula uketshezi okuthembekile nokusebenzayo ezinhlelweni zemboni.

Ihambisana namazinga okuhlola aqinile ukuze kuqinisekiswe ukusebenza kahle nokuphepha. I-valve iklanyelwe ukumelana nezingcindezi eziphezulu namazinga okushisa kuyilapho igcina uphawu oluqinile ukuvimbela ukuvuza. Ifaka idizayini yesikulufu sangaphandle nejoka (OS&Y) ukuze isebenze kalula kanye nenkomba ebonakalayo yendawo yevalvu.

Ukwakhiwa kwensimbi yensimbi kunikeza ukuqina nokumelana nokugqwala, okwenza kube kufanelekile ezindaweni eziningi eziyinselele. Ukuthobela kwayo amazinga e-API600 kuqinisekisa ukuthi ihlangabezana nezimfuneko eziqinile zemboni zekhwalithi nokusebenza.

Izici

Uhlolojikelele Lomkhiqizo

Ububanzi bungakhiwa ukuze buhambisane nohlelo lwakho lokusebenza, ngokwakhiwa komzimba, izinto ezibonakalayo, nezici ezihambisanayo ezithuthukisiwe ukuze zihlangabezane nezidingo zenqubo yakho. Njengoba isitifiketi se-ISO 9001, sisebenzisa izindlela ezihlelekile zokuqinisekisa ikhwalithi ephezulu, ungaqinisekiswa ngokwethembeka okuvelele nokusebenza kokuvala ngokuphila kokuklama kwempahla yakho.

Imfuneko Yezobuchwepheshe

· Idizayini Nokukhiqiza Ivumelana Ne-API 600

· Ubukhulu be-Flange Buvumelana ne-ASME B16.5

· Ubukhulu bobuso nobuso Buvumelana ne-ASME B16.10

· Testing Conform to API 598

· Imodi yokushayela: isondo lesandla, igiya le-bevel, ugesi

Ukucaciswa

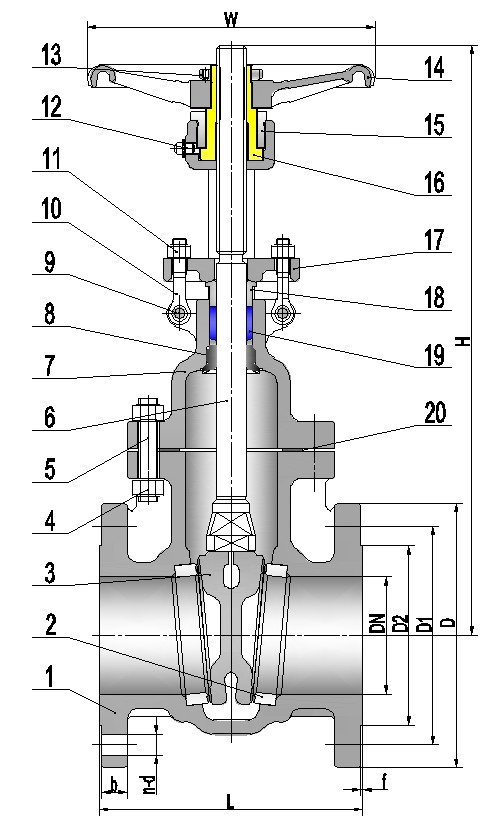

| Cha. | Igama Lengxenye | Okubalulekile |

| 1 | Umzimba | I-A216-WCB |

| 2 | Indandatho Yesihlalo | I-A105+CR13 |

| 3 | I-Wedge | I-A216-WCB+CR13 |

| 4 | I-Bonnet Stud Nut | I-A194-2H |

| 5 | I-Bonnet Stud | I-A193-B7 |

| 6 | Isiqu | I-A182-F6a |

| 7 | Ibhonethi | I-A216-WCB |

| 8 | I-Stem Back Seat | I-A276-420 |

| 9 | Iphinikhodi ye-eyebolt | Insimbi Yekhabhoni |

| 10 | Ibhodlela lamehlo | Insimbi Yekhabhoni |

| 11 | I-Eyebolt Nut | Insimbi Yekhabhoni |

| 12 | Ukufaka Amafutha | I-Brass+Steel |

| 13 | I-Handwheel Nut | Insimbi Yekhabhoni |

| 14 | Isondo lesandla | I-Ductile Iron |

| 15 | I-Yokesleeve Jam nut | Insimbi Yekhabhoni |

| 16 | I-Yokesleeve | Ibhulonzi |

| 17 | I-Gland Flange | I-A216-WCB |

| 18 | Indlala | I-A276-420 |

| 19 | Ukupakisha | I-graphite |

| 20 | I-Bonnet Gasket | I-graphite+304 |

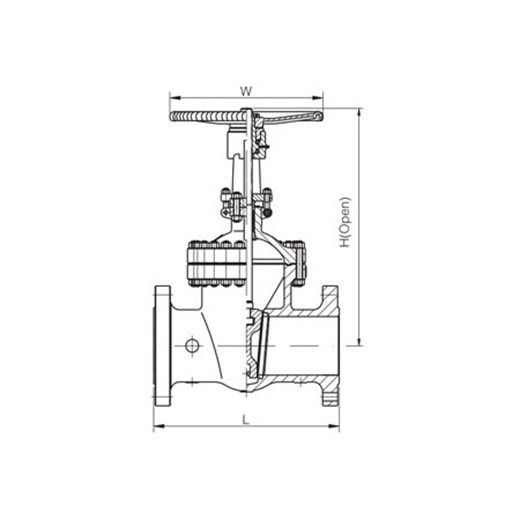

Idatha yobukhulu

| I-NPS | 2 | 2½ | 3 | 4 | 5 | 6 | 8 | 10 | 12 | 14 | 16 | 18 | 20 | 24 |

| L | 177.8 | 190.5 | 203.2 | 228.6 | 254 | 266.7 | 292.1 | 330.2 | 355.6 | 381 | 406 | 432 | 457 | 508 |

| D | 152 | 178 | 191 | 229 | 254 | 279 | 343 | 406 | 483 | 533 | 597 | 635 | 699 | 813 |

| D1 | 120.7 | 139.7 | 152.4 | 190.5 | 215.9 | 241.3 | 298.5 | 362 | 431.8 | 476.3 | 539.8 | 577.9 | 635 | 749.3 |

| D2 | 92 | 105 | 127 | 157 | 186 | 216 | 270 | 324 | 381 | 413 | 470 | 533 | 584 | 692 |

| b | 14.4 | 16.4 | 17.9 | 22.4 | 22.4 | 23.9 | 26.9 | 28.9 | 30.2 | 33.9 | 35.4 | 38.4 | 41.4 | 46.4 |

| nd | 4-19 | 4-19 | 4-19 | 8-19 | 8-22 | 8-22 | 8-22 | 12-25 | 12-25 | 12-29 | 16-29 | 16-32 | 20-32 | 20-35 |

| f | 1.6 | 1.6 | 1.6 | 1.6 | 1.6 | 1.6 | 1.6 | 1.6 | 1.6 | 1.6 | 1.6 | 1.6 | 1.6 | 1.6 |

| H | 345 | 387 | 430 | 513 | 583 | 648 | 790 | 935 | 1100 | 1200 | 1330 | 1480 | 1635 | 1935 |

| W | 200 | 200 | 250 | 250 | 300 | 300 | 350 | 400 | 450 | 500 | 500 | 600 | 600 | 650 |